+86-18732831111

+86-18732831111

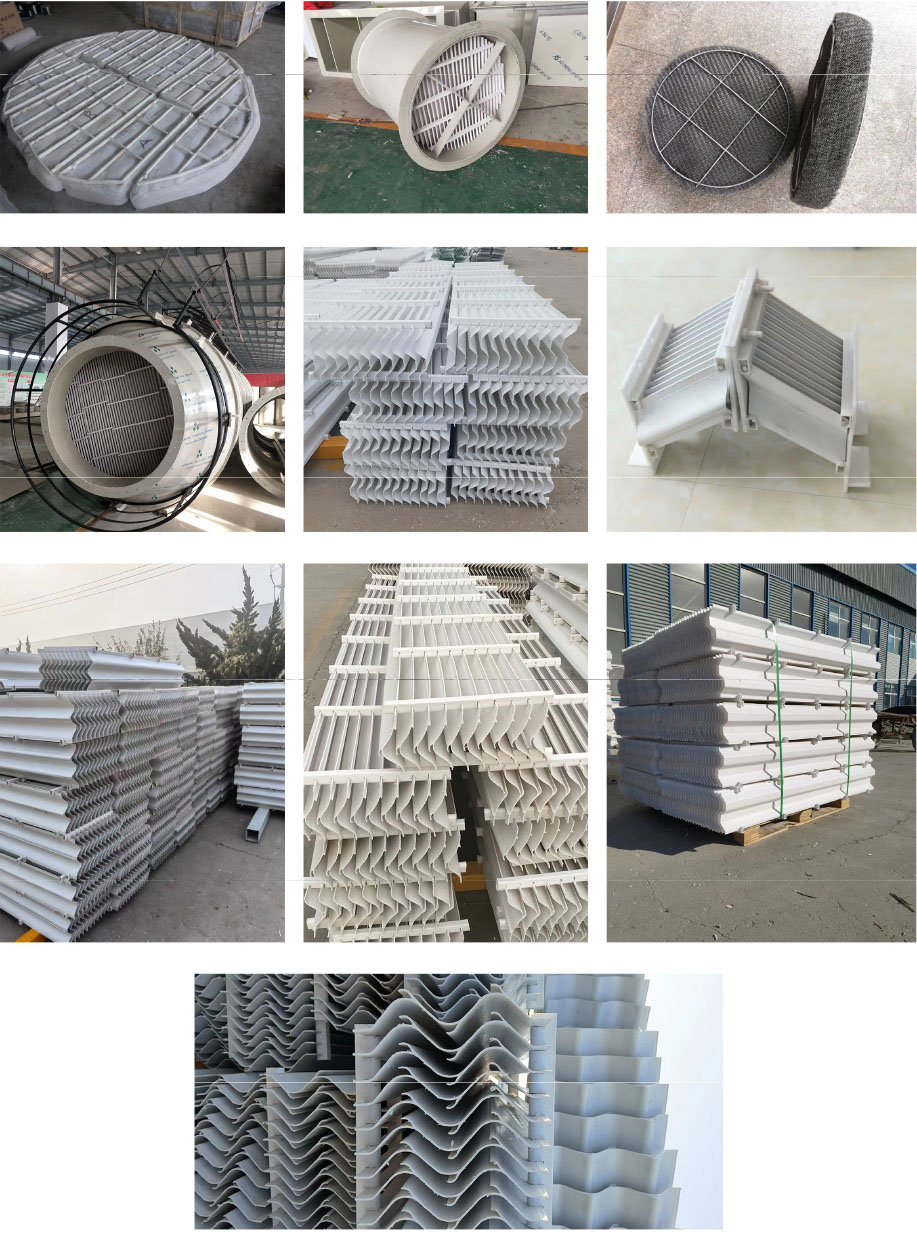

Hebei Shengrun FRP Co., Ltd. achieves ultra-low emissions of particulate matter in the tube bundle dust collector and tube bundle mist eliminator tube bundle mist eliminator DN315mm/400mm

The characteristics of the operating environment of the tube bundle dust removal device are the saturated clean flue gas containing a large number of liquid droplets at~50 ℃, characterized by a large amount of fog droplets, a wide range of fog droplet size distribution, composed of slurry droplets, condensate droplets, and dust particles; Dust removal mainly involves removing slurry droplets and dust particles. The condensation of small droplets and particles. A large number of small droplets and particles have a significantly increased probability of collision under high-speed motion conditions, making them easy to condense and aggregate into large particles, thus achieving separation from the gas phase. The capture of large liquid droplets and liquid film on the wall of the dust collector cylinder will capture small liquid droplets that come into contact with their surface, especially the excessively thick liquid film on the surface of the booster and separator blades. Under the action of high-speed airflow, a large number of large liquid droplets will be thrown out from the surface of the blades, forming a droplet layer composed of large liquid droplets on the upper part of the blades, and small liquid droplets passing through the droplet layer will be captured, After the large droplets become larger, they fall back onto the surface of the blade and become large droplets again, achieving the capture of small droplets. The liquid droplet removal under centrifugal separation is accelerated by an accelerator, and the airflow rotates at high speed and moves upwards. The small mist droplets and dust particles in the airflow are separated from the gas under centrifugal force and move towards the surface of the cylinder. The high-speed rotating airflow breaks through and the trapped droplets form a rotating liquid film layer on the wall of the cylinder. The removal of small droplets and dust particles separated from gas from flue gas.

Hebei Shengrun FRP Co., Ltd. achieves ultra-low emissions of particulate matter in the tube bundle dust collector and tube bundle mist collector.

The higher the rotational flow rate of gas captured by multi-stage separators for different particle size droplets, the better the centrifugal separation effect. The larger the amount of captured droplets, the thicker the liquid film formed, the greater the operating resistance, and the easier it is to generate secondary droplets; Therefore, a multi-stage separator is used to remove fog droplets at different flow rates, ensuring the dust removal effect under low operating resistance.

Key Technologies of Tube Bundle Dust Remover (Mist Remover)

Modified Polymer Materials

• Meet specific strength and stiffness requirements;

• Specific surface finish of the material;

• Hydrophobicity.

Process Structure Design of Tube Bundle Dust Remover (Mist Remover)

The selection of the average flow rate of the gas cross-section and the diameter and height of the cylinder;

The selection of dust removal separation efficiency and the angle of the booster and separator blades;

Control measures for the thickness of the liquid film on the cylinder wall;

Adjusting the distribution of airflow and controlling resistance measures in the dust collector;

Adapt to operating conditions of different loads ranging from 30% to 115%;

• Dust collector flushing water system.

Tubular dust collector (mist eliminator) - Technical characteristics

High dust removal efficiency, reaching below 5mg/Nm3;

Eliminate gypsum rain;

Low operating resistance without additional operating costs;

Simply use the existing absorption tower space for renovation without changing the external structure of the absorption tower;

The renovation installation period is short and can be completed within three weeks;

Low investment cost, low operating expenses, and good economy.

Technical advantages - Compared with traditional mist eliminators, mist eliminators rely on the inertia and gravity of droplets in the flue gas as their working principles. The design flow rate is generally selected between 3.5 and 5.5m/s. The working principle and operating flow rate of a foldable mist eliminator determine the removal of small droplets, and even a multi-layer ridge mist eliminator cannot achieve an outlet dust concentration of 5mg/Nm3